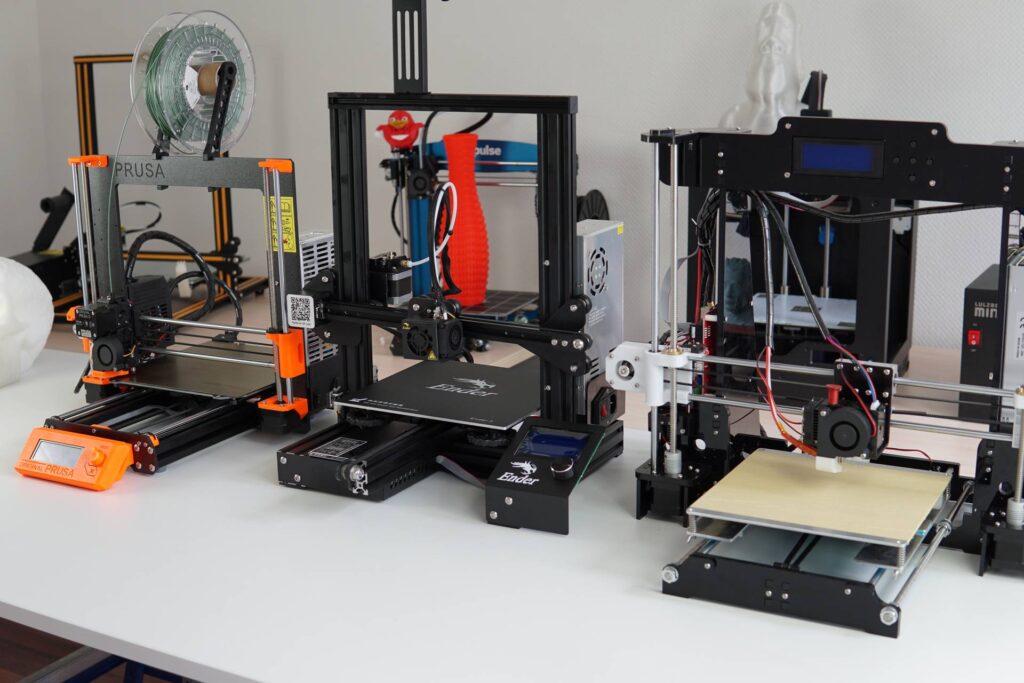

Fused Deposition Modeling (FDM) 3D Printer

Fused Deposition Modeling (FDM) is a popular 3D printing technology that uses a thermoplastic filament to create 3D objects. The FDM process involves melting the filament and extruding it layer by layer to build up the desired shape. This is done using a motor-driven extruder that moves back and forth across the build area, laying down the melted filament to form each layer.

Technical Details of Our High-Quality FDM 3D Printers.

- Layer resolution: up to 50 microns

- Filament diameter: 1.75 mm or 2.85 mm

- Build volume: up to 300 x 300 x 400 mm

- Nozzle temperature: up to 300 degrees Celsius

- Heated build platform: up to 110 degrees Celsius

Features & Amenities

No more boredom at work.

Lorem ipsum dolor sit amet, consectetur adipiscing elit.

free flowing coffee/tea

Dictum ultrices quisque sit suscipit et vulputate turpis taciti maximus

Free wifi access

Dictum ultrices quisque sit suscipit et vulputate turpis taciti maximus

24 hour open

Dictum ultrices quisque sit suscipit et vulputate turpis taciti maximus

Free parking

Dictum ultrices quisque sit suscipit et vulputate turpis taciti maximus

Support Center

Dictum ultrices quisque sit suscipit et vulputate turpis taciti maximus

Business community

Dictum ultrices quisque sit suscipit et vulputate turpis taciti maximus

Weekly Events

Dictum ultrices quisque sit suscipit et vulputate turpis taciti maximus

Library Access

Dictum ultrices quisque sit suscipit et vulputate turpis taciti maximus

Benefits of Renting

Affordable rates

Latest technology

Convenience

Ready to start printing with an FDM 3D printer? Contact us today to learn more about our rental options and to place your order. We look forward to helping you bring your ideas to life!

Most popular Questions

What is FDM 3D printing?

Fused Deposition Modeling (FDM) is a type of 3D printing technology that uses a thermoplastic filament to create 3D objects layer by layer.

What types of materials can be used with FDM printers?

FDM printers typically use a variety of thermoplastics, including ABS, PLA, PETG, nylon, and TPU.

What is the layer resolution of your FDM printers?

Our FDM printers have a layer resolution of up to 50 microns, which allows for highly-detailed and precise prints.

What is the build volume of your FDM printers?

Our FDM printers have a build volume of up to 300 x 300 x 400 mm, which allows for larger prints and more design flexibility.

Can FDM printers create functional parts?

Yes, FDM printers can create functional parts with varying levels of complexity, making them ideal for prototyping and small-batch manufacturing.

Do you offer custom sizing options for FDM prints?

Yes, we can create custom-sized prints based on your specific needs and requirements.